Home

Home

In the evolving landscape of material science, the significance of air permeability testing has become increasingly prominent, shedding light on the intricate relationship between material performance and airflow characteristics. Recent industry reports indicate that materials with optimal air permeability can enhance insulation properties and reduce energy consumption by up to 30%, making them pivotal in industries ranging from construction to textiles. The integration of innovative air permeability testers has revolutionized the way manufacturers assess their products, ensuring compliance with durability standards and performance metrics.

Dr. Emily Carter, a leading expert in materials engineering, emphasizes the critical role of air permeability in determining a material's effectiveness:

"Understanding the airflow through materials not only helps in optimizing their physical properties but also provides insights into sustainability practices."This statement underscores the growing trend towards utilizing air permeability testers to achieve better performance benchmarks and environmental efficiency. As manufacturers seek to enhance their competitive edge, the adoption of advanced air permeability testing technology becomes not just beneficial but essential, promising a future where material performance aligns closely with sustainability goals.

Air permeability plays a crucial role in determining the functionality and performance of various materials, particularly in industries such as textiles, construction, and medical devices. According to a report by the Textile Research Journal, materials with optimal air permeability are essential for enhancing breathability and moisture management in clothing, leading to improved comfort and wearability. For example, garments made from fabrics with a permeability rate of 200-500 L/m²/s are considered ideal for activewear, ensuring that sweat evaporates efficiently while maintaining a comfortable microclimate against the skin.

Moreover, in the construction sector, air permeability testing is vital for assessing the energy efficiency and durability of building materials. The Building Research Establishment (BRE) has highlighted that materials with lower permeability can significantly reduce heat loss in buildings, contributing to energy savings of up to 30%. This is essential for compliance with modern building regulations and standards, showcasing the importance of selecting appropriate materials that balance air flow with thermal insulation. Consequently, the science of air permeability is not merely a measurement but a key factor in enhancing the overall functionality and sustainability of materials across diverse applications.

Air permeability is crucial for evaluating material functionality. This chart illustrates the air permeability levels of various materials, showing how cotton and nylon are significantly more permeable compared to leather and polyester.

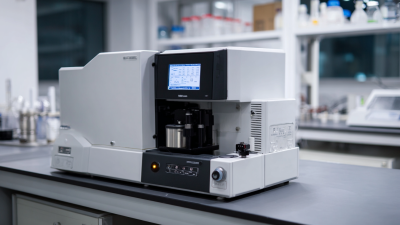

In modern material science, air permeability testers play a crucial role in evaluating and enhancing the performance of various materials. These testers measure how easily air can pass through a material, providing insights into its porosity and breathability. This data is essential for industries such as textiles, packaging, and construction, where the ability of a material to manage air flow significantly impacts product functionality and user experience. By employing sophisticated technologies, researchers can precisely determine the air permeability of materials, leading to innovations in design and performance optimization.

Furthermore, air permeability testers facilitate the development of advanced materials that meet specific criteria for different applications. For instance, in the textile industry, understanding the airflow characteristics helps in creating fabrics that offer comfort and moisture management. In construction, materials with ideal air permeability contribute to energy efficiency and indoor air quality. As material science continues to evolve, the integration of air permeability testing is proving indispensable, driving forward applications that range from breathable clothing to sustainable building materials, ultimately revolutionizing how we interact with our environment.

Innovative techniques in measuring air permeability have ushered in a new era for material performance evaluation. By employing advanced methodologies such as dynamic air permeability testing and digital imaging, researchers can now assess how materials respond to airflow in real-time. These methods provide a more nuanced understanding of material behavior, enabling engineers and designers to select the right components for specific applications, from breathable fabrics to efficient insulation in buildings.

Furthermore, the integration of artificial intelligence and machine learning in air permeability testing has significantly enhanced the accuracy and efficiency of measurements. Automated systems can now analyze vast datasets, identifying patterns that were previously difficult to discern. This not only accelerates the testing process but also contributes to more sustainable product development, as manufacturers can optimize material properties with precision. As a result, industries ranging from textiles to construction are able to innovate more rapidly, leading to products that meet higher performance standards while also addressing environmental concerns.

The impact of air permeability on material selection and performance cannot be overstated. Air permeability, defined as the ability of air to pass through a material, plays a crucial role in various applications, including textiles, construction, and packaging. Materials with high air permeability can enhance breathability, which is vital for clothing, while low-permeability materials might be preferred for insulation in building structures. Selecting the right material based on its air permeability can significantly enhance the functionality and durability of the final product.

**Tips:** When choosing materials, consider the specific application requirements. For instance, if developing activewear, opt for fabrics with higher air permeability to improve comfort and moisture management. Conversely, if your product requires insulation, such as in soundproof walls, select materials that minimize air flow. Additionally, always test for air permeability, as it can vary significantly even among materials deemed similar.

In recent years, advancements in air permeability testing technologies have allowed manufacturers to assess material performance with unprecedented accuracy. By utilizing precise testers, businesses can make informed choices in their material selection processes, ensuring they meet the necessary performance standards while aligning with their sustainability goals. This revolution not only fosters innovation but also enhances the end-user experience by providing products that perform as intended.

| Material Type | Air Permeability (m³/m².h.kPa) | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Cotton Fabric | 50-100 | Clothing, Bed Linens | Breathable, Soft | Wrinkles Easily |

| Polyester | 10-50 | Sportswear, Outdoor Gear | Durable, Moisture-Wicking | Less Breathable |

| Gore-Tex | 5-15 | Rainwear, Outdoor Clothing | Waterproof, Windproof | Higher Cost |

| Nylon | 20-80 | Backpacks, Tents | Lightweight, Strong | Can Absorb Water |

| Wool | 30-60 | Sweaters, Insulation | Insulating, Natural Fiber | Can Shrink When Washed |

As industries continue to evolve, the demand for innovative material performance assessment techniques grows. Air permeability testing has emerged as a critical factor in evaluating materials’ suitability for various applications, particularly in textiles, construction, and filtration systems. The advancements in testing technologies, including automated systems and advanced sensors, provide precise and rapid results, enabling manufacturers to refine their products for optimal efficiency.

Looking ahead, future trends in air permeability testing are expected to incorporate machine learning and AI-driven analysis, offering deeper insights into material behavior under various conditions. These technologies will allow for real-time monitoring and predictive modeling, reducing the time and costs associated with traditional testing methods. Additionally, the integration of sustainable materials and biodegradable options into permeability testing protocols will drive innovation, aligning with the growing focus on environmental responsibility in material development. As researchers and manufacturers collaborate, we can anticipate a new era where air permeability testing not only enhances performance but also supports the creation of more sustainable materials tailored to meet evolving market demands.